Dry Etching and Sputtering Module

Lam Research AutoEtch 490 System (DRY-490)

Clean

Specifications

| Fluorine & Chlorine based parallel plate system for etching polysilicon & nitride with endpoint detection | ||

|---|---|---|

| Gases available | : | Cl2, SF6, He, O2, C2F6 |

| RF power source | : | 650W(max) at 13.56MHz |

| Substrate size | : | 4” single wafer |

| Polysilicon etch with chlorine based gas | ||

| E/R | : | 4000 Ȧ/min |

| Selectivity to oxide | : | 20:1 |

| Selectivity to photoresist | : | 1.5:1 |

| Uniformity | : | 7.5% |

| Polysilicon etch with fluorine based gas | ||

| E/R | : | 5000 Ȧ/min |

| Selectivity to oxide | : | 20:1 |

| Selectivity to photoresist: | : | 1.5:1 |

| Uniformity | : | 10% |

| Silicon Nitride etch with fluorine based gas | ||

| E/R | : | 1000 Ȧ/min |

| Selectivity to oxide: | : | 3:1 |

| Selectivity to photoresist | : | 1.5:1 |

| Uniformity | : | 5% |

STS ICP Poly-Si Etcher (DRY-ICP-Poly)

Clean/Semi-clean

Specifications

| Gases available | : | HBr, Cl2, O2, N2, He & Ar |

|---|---|---|

| RF power source | : | 1x 1000W(max) at 13.56MHz for Coil electrode, 1x 300W(max) at 13.56MHz for Platen electrode |

| Electrode coolant system | : | 20 oC |

| High speed turbo molecular pump | : | pumping speed of 1000 L/s at 36000 rpm |

| Fully automatic loadlock transfer system | ||

| Substrate size | : | 4” single wafer |

| Polysilicon etch | ||

| Minimum line/space | : | 0.5 µm |

| Low rate polysilicon etch E/R | : | ~ 900 Ȧ/min |

| Selectivity to oxide | : | 13:1 |

| Selectivity to photoresist | : | 12.5:1 |

| Uniformity | : | 5% |

| Normal rate polysilicon etch | ||

| E/R | : | >1800 Ȧ/min |

| Selectivity to photoresist | : | 2.5:1 |

| Uniformity | : | 5% |

STS ICP GaN Etcher (DRY-ICP-GaN)

Non-Standard

Specifications

| Gases available | : | BCl3, Cl2, CH4, SF6, O2, He & Ar |

|---|---|---|

| RF power source | : | 1x 1000W(max) at 13.56MHz for Coil electrode, 1x 300W(max) at 13.56MHz for Platen electrode |

| Electrode coolant system | : | 5 to 30 oC |

| High speed turbo molecular pump | : | pumping speed of 1000 L/s at 36000 rpm |

| Fully automatic loadlock transfer system | ||

| Substrate size | : | 2" or 6” single wafer or specimens |

| GaN etch | ||

| E/R | : | ~5000 Ȧ/min |

| Selectivity to oxide | : | 10:1 |

| Sapphire etch | ||

| E/R | : | ~700 Ȧ/min |

| Selectivity to oxide | : | 1.5:1 |

STS ICP DRIE Silicon Etcher (DRY-ICP-Si)

Clean

Specifications

| Gases available | : | C4F8, SF6, O2, N2, He & Ar |

|---|---|---|

| RF power source | : | 1x 1000W(max) at 13.56MHz for Coil electrode, 1x 300W(max) at 13.56MHz for Platen electrode |

| Electrode coolant system | : | 5 to 30 oC |

| High speed turbo molecular pump | : | pumping speed of 1000 L/s at 36000 rpm |

| Fully automatic loadlock transfer system | ||

| Substrate size | : | 4" wafer |

| Silicon etch | ||

| Minimum Line/Space | : | 0.5 µm |

| Low Rate Silicon Etch E/R | : | From 500 Ȧ/cycle |

| Normal Rate Silicon Etch E/R | : | Up to 2 µm/min |

| Selectivity to Photoresist | : | >50:1 |

| Selectivity to Oxide | : | >80:1 |

| Uniformity | : | 7% |

STS AOE Etcher (DRY-ICP-AOE)

Clean

Specifications

| Gases available | : | C4F8, CF4, CHF3, O2, N2, H2, He & Ar |

|---|---|---|

| RF power source | : | 1x 3000W(max) at 13.56MHz for Coil electrode, 1x 600W(max) at 13.56MHz for Platen electrode |

| Electrode coolant system | : | -5 to 30 oC |

| High speed turbo molecular pump | : | pumping speed of 2000 L/s at 48000 rpm |

| Fully automatic loadlock transfer system | ||

| Substrate size | : | 4" single silicon or quartz wafer |

| Silicon Oxide etch | ||

| Minimum Line/Space | : | 0.5 µm |

| Silicon Oxide Etch E/R | : | > 2500 Ȧ/min |

| Selectivity to Photoresist | : | >4:1 |

| Selectivity to Polysilicon | : | >15:1 |

| Uniformity | : | 7.5% |

PS210 Photo Resist Asher (DRY-210)

Clean

Branson IPC3000 Photo Resist Asher (DRY-3000-1 To DRY-3000-2)

Semi-clean/Non-standard

Branson IPC3000 Photo Resist Asher (Dry-3000)

Non-Standard

Oxford Plasmalab 80 Plus Reactive Ion Etcher (DRY-Oxford-RIE)

Non-Standard

Specifications

| Gases available | : | CHF3, SF6, O2, CF4, Ar, N2, He & H2 |

|---|---|---|

| RF power source | : | 500W at 13.56MHz |

| Huber electrode coolant system | : | -40 to 200 oC |

| Substrate size | : | 4", up to 3 wafers per run or specimen |

| Silicon Dioxide Etch | ||

| E/R | : | ~363 Ȧ/min for LTO |

| E/R | : | ~352 Ȧ/min for thermal oxide |

| Selectivity to photoresist | : | 2.6:1 |

| Selectivity to Silicon Nitride | : | 0.8:1 |

| Selectivity to Silicon | : | 6.7:1 |

| Uniformity | : | 3.6% |

| Silicon Nitride Etch | ||

| E/R | : | ~810 Ȧ/min |

| Selectivity to photoresist | : | 1.5:1 |

| Selectivity to Silicon Dioxide | : | 2.1:1 |

| Selectivity to Silicon | : | 5.4:1 |

| Uniformity | : | 5.8% |

AST Cirie 200 Etcher (DRY-METAL)

Semi-clean

Specifications

| Chlorine & Fluorine based barrel type system for etching aluminum | ||

|---|---|---|

| Gases available | : | Cl2, BCl3, CF4, CHF3, He, Ar, O2 & N2 |

| RF power source | : | 1000W(max) at 13.56MHz |

| Bias power source | : | 1000W(max) at 13.56MHz |

| Substrate size | : | 4" wafers |

| Aluminum Etch | ||

| Al etch rate | : | 1700 Ȧ/min |

| PR etch rate | : | 1000 Ȧ/min |

| SiOx etch rate | : | 300 Ȧ/min |

Cello Nasca-20 Plus Etcher (DRY-ICP-GaN2)

Non-Standard

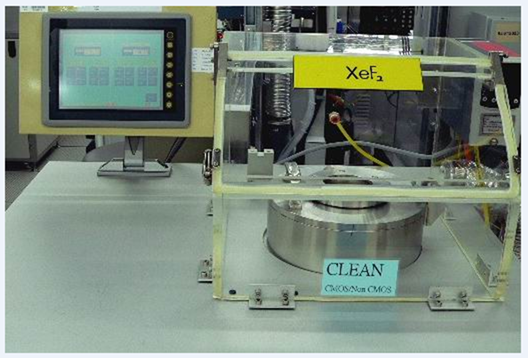

XeF2 Isotropic Silicon Etcher (DRY-XeF2)

Clean

TRION ICP / Reactive Ion Etcher (DRY-TRION)

Clean/Semi-clean

Specifications

| Gases available | : | CHF3, SF6, O2, CF4, Ar, N2, He and H2 |

|---|---|---|

| ICP power source | : | 600W (max) at 13.56MHz |

| RF power source | : | 600W (max) at 13.56MHz |

| Electrode coolant system | : | 0 to 30 oC |

| Substrate size | : | 4", up to 3 wafers per run or specimens |

| Silicon Dioxide Etch | : | ~500 Ȧ/min |

| Silicon Nitride Etch | : | ~850 Ȧ/min |

Varian 3180 Sputtering System (SPT-3180)

Semi-clean

Specifications

| Gases available | : | Ar & N2 |

|---|---|---|

| DC sputtering power source | : | 3 x 12KW |

| RF back sputtering power source | : | 600W at 13.56MHz |

| Fully automatic wafer handling system | ||

| Substrate size | : | 4" wafer |

| Chamber pressure | : | 5 x 10-7 torr |

| Target available | : | Pure Al, Al-Si & Ti |

| Sputtering rate ( Ȧ/sec) | ||

~160 Ȧ/sec for pure Al |

||

~180 Ȧ/sec for Al/Si (1%) |

||

~40 Ȧ/sec for Ti |

||

No Photoresist on wafer is allowed |

||

CVC 601 Sputtering System (SPT-CVC)

Non-Standard

Specifications

| Gases available | : | Ar & N2 |

|---|---|---|

| DC sputtering power source | : | 1 x 3 KW |

| RF sputtering power source | : | 1200W at 13.56MHz |

| Chamber pressure | : | 5 x 10-7 torr |

| Substrate size | : | 2", 4"& 6" wafers or 4" square glass substrate |

| Target available | : | Cu, TiW & Au |

| Target available on request | : | Ti, Cr & Al-Si |

| Sputtering rate (Ȧ/min): | ||

~500 Ȧ/min for Al-Si |

||

~175 Ȧ/min for TiW |

||

~160 Ȧ/min for Au |

||

~1000 Ȧ/min for Cu |

||

No Photoresist on wafer is allowed |

||

ARC-12M Sputtering System (SPT-ARC)

Non-Standard

Specifications

| Gases available | : | Ar, O2 & N2 |

|---|---|---|

| DC sputtering power source | : | 2 x 250W |

| RF sputtering power source | : | 600W at 13.56MHz |

| Chamber pressure | : | 1.5 x 10-5 torr |

| Substrate size | : | 2", 4" wafer or square glass, or specimens |

| Target available | : | Ag, Al, Al/Si (1%), Au, Cu, Cr, Hf, Mo, Pt, SiN, Ti, TiW |

No Photoresist on wafer is allowed |

||

Denton Explorer 14 Sputtering System (SPT-DENTON)

Non-Standard

Specifications

| Gases available | : | N2 (for venting)& Ar |

|---|---|---|

| DC sputtering power source | : | 2 x 600V |

| RF sputtering power source | : | 600W at 13.56MHz |

| Chamber pressure | : | 5 x 10-7 torr |

| Substrate size | : | 2" to 6" wafer or 4" square glass, or specimen |

| Target available | : | TiW, Ti, Al(pure), Cu & AlSi |

| Sputtering rate (Ȧ/min): | ||

~88 Ȧ/min for Ti |

||

~148 Ȧ/min for TiW |

||

~100 Ȧ/min for Al (pure) |

||

~127 Ȧ/min for AlSi |

||

~321 Ȧ/min for Cu |

||

Cooke E-Beam Evaporation System (SPT-EV1 to SPT-EV2)

Semi-clean/Non-Standard

Specifications

| Gases available | : | N2 |

|---|---|---|

| E-beam power source | : | 1x 3KW |

| Chamber pressure | : | 8 x 10-7 torr |

| Substrate size | : | pumping speed of 1000 L/s at 36000 rpm |

| Substrate size | : | 2" or 4" wafers |

| Source available in Phase II | : | Al, Ni, Mo, Ti, Cr |

| Source available in EC | : | Al, Ni, Ti, Au, Cr, Pt, Fe, SiO2, Ag |

| Sputtering rate for Cooke in Phase II (Ȧ/min): | ||

~270 Ȧ/min for Mo |

||

~670 Ȧ/min for Ni |

||

~500 Ȧ/min for Ti |

||

~300 Ȧ/min for Al |

||

AST Peva-600EI E-Beam Evaporation System (SPT-AST600)

Non-Standard

AST Peva-450I E-Beam Evaporation System (SPT-AST450)

Non-Standard

Edward Sputter Coater (SPT-Edward)

Non-Standard

Nano-master NSC3000 Sputtering System (SPT-NSC3000)

Non-Standard

Specifications

| Gases available | : | O2, N2 & Ar |

|---|---|---|

| DC sputtering power source | : | 1 x 1KW |

| Chamber pressure | : | 5 x 10-6 torr |

| Substrate size | : | 2", 4" wafer or square glass, or specimens |

| Target available | : | Al, Ti, Cr, Al-Si, Ni & Mo |

| Sputtering rate (Ȧ/min): | ||

40 Ȧ/min for Al |

||

50 Ȧ/min for Ti |

||

70 Ȧ/min for Cr |

||

50 Ȧ/min for TiW |

||

50 Ȧ/min for Ni |

||