Photolithography Module

Nanoscribe 3D Printer (PHT-P1)

Clean/Semi-clean/Non-Standard

Specifications

| Resolution (depends on the objective lens and resist) | : |

- 3D lateral feature size: ≤200 nm - 2D lateral resolution: ≤500 nm - Vertical resolution: ≤1,500 nm |

|||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed | : |

- Beam scanning speed: 10 mm/s - Piezo scanning speed: 100 µm/s |

|||||||||||||||||||||||||||||||||

| Range | : | - Motorized xy scanning stage range: 100 x 100 mm² -x-y-z piezo range: 300 x 300 x 300 µm³ -x-y galvo scan range 200 - 1000 µm Ø dependent on scanning objective |

|||||||||||||||||||||||||||||||||

| Maximum structure height | : | - IP-Q 10x lens DiLL: 8 mm - IP-S 25x lens DiLL: 3 mm - IP DiP 63x lens DiLL: 3 mm - Oil immersion with 170 µm glass: 150 µm |

|||||||||||||||||||||||||||||||||

| Minimum feature size | : | -10x lens: ~2 µm x, y and ~10 µm z -25x lens: 0.6 µm x, y and ~3.3 µm z -63x lens: 150 nm x, y and 800 nm z |

|||||||||||||||||||||||||||||||||

| Objectives | : | 1. Immersion Objective: 63x, NA=1.4; WD=190 um, for high-resolution structures, printing field (Galvo Ø) = 200 um; Typical slicing distance = 0.3 µm; Typical hatching distance=0.2 µm 2. Immersion Objective: 25x; NA=0.8; WD=380 um, for mesoscale structures; Printing field (Gavle Ø) = 400 µm; Typical slicing distance =1 µm; Typical hatching distance=0.5 µm 3. Air Objective: 20x, NA=0.5; WD=2100 um, for 2D maskless lithography; Printing field (Galvo Ø) = 600 µm; Typical slicing distance=3-6 µm; Typical hatching distance= 0.7-1.2 µm 4. Immersion Objective: 10x, NA=0.3; WD=700 um, for rapid prototyping; Printing field (Galvo Ø) =1000 µm; Typical slicing distance= 5 µm; Typical hatching distance =1 µm |

|||||||||||||||||||||||||||||||||

| Sample holders | : |

|

|||||||||||||||||||||||||||||||||

| Printing configuration | : |

|

ASML Stepper (PHT-S1)

Clean/Semi-clean

Karl Suss Bonder XB8 (PHT-B2)

Non-Standard

Specifications

| Adhesive, Anodic, Eutectic bonding and Silicon fusion prebonding | ||

|---|---|---|

| Wafer size | : | > 2 cm x 2 cm, 4", 6" & 8" |

| Substrate material | : | Silicon or Pyrex Glass |

| Pressure | : | 1x10e-5 mbar to 3 bars |

| Bonding force | : | 3500 N ~ 100K N (8") |

| Temperature | : | RT to 500 ºC |

| Controllable Voltage range | : | 0 – 2000 V |

| Controllable Current range | : | 0-15 mA |

SET ACCµRA100 Flip-Chip Bonder (PHT-B3)

Non-Standard

Heidelberg Maskless Aligner µMLA (PHT-A9)

Non-standard

Karl Suss MA6 #1 and #2 (PHT-A5 and PHT-A7)

Clean/Semi-clean/Non-Standard

Specifications

| Light source illumination | : | i-line (365 nm) |

|---|---|---|

| Resolution | : | 1 um |

| Substrate size | : | > 5 mm2 to 2" or 4" |

| Photomask size | : | 5" square |

| Exposure modes | : | Contact (soft, hard, low vacuum and Vacuum) Proximity (exposure gap 1-300um); Flood Exposures |

| Alignment methods | : | Top Side Alignment (TSA); Bottom Side Alignment (BSA) |

| Alignment accuracy | : | TSA (down to 0.5 µm); BSA (down to 1 µm) |

| No. of machines installed | : | 2 |

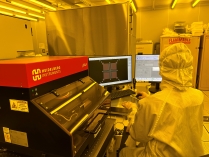

AB-M Aligner #1 (UV)/(DUV) and #2 (UV) (PHT-A1 and PHT-A2)

Semi-clean/Non-Standard

Specifications

| Light source illumination | : | DUV / UV wavelength selectable (500W Mercury DUV lamp) |

|---|---|---|

| Alighment printing mode | : | Manual |

| Soft contact | : | Contact vacuum adjustable |

| Hard contact | : | Full vacuum contact |

| Photomask | : | 5" square or 7" square |

| Substrate size | : | > 5 mm2 to 4" square, or 6" |

| Special feature | : | Backside alignment using Infra-red |

| No. of machines installed | 2 |

NILT Nanoimprint (PHT-N1)

Clean/Semi-Clean

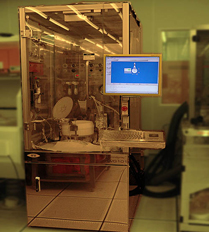

SVG88 Coater Track and SVG88 Developer Track (PHT-T1 and PHT-T2)

Clean/Semi-clean

Specifications

| Automatic tracks for resist coating and developing | ||

|---|---|---|

| No. of tracks | : | 2 |

| Coat track feature | : | Vapor prime chill plate |

| : | Coat module Backside rinse |

|

| : | Frontside edge bead remover 2 hot plate ovens |

|

| Develop track | : | Developer module, chill plate, 2 hot plate ovens |

| Coating uniformity | : | ± 0.3 % |

| Wafer size | : | 4" and 6" |

| Wafer loading/unloading | : | Cassette to cassette |

EVG Spray Coater (PHT-SC5)

Clean/Semi-clean/Non-Standard

Specifications

| Speed range | : | up to 10000 rpm |

|---|---|---|

| Ramp up speed | : | 0-40000 rpm/s |

| Heat chuck temperature | : | up to 70 ± 1 oC |

| Spray speed integrate with heat chuck | : | < 1500 rpm |

| Spray coating nozzle | : | Ultrasonic Atomizer Nozzle |

| Syringe dispense rate | : | 0.01 ml/s to 5 ml/s |

| Substrate size | : | Up to 200 mm or 150 mm x 150 mm |

SUSS Coater (PHT-SC1)

Semi-clean/Non-Standard

CEE Coater (PHT-SC3)

Clean/Semi-clean

Desktop Coater (PHT-SC2)

Non-Standard

Solitec Coater #1 (PHT-SC4)

Non-Standard

High Temperature Conventional Oven (PHT-O1 to PHT-O4, PHT-O6 to PHT-O9)

Clean/Semi-clean/Non-Standard

Vacuum Oven (PHT-O5)

Non-Standard

Unitemp Reflow Oven (PHT-O11) (PHT-B3 Flip-Chip Bonder user only)

Non-Standard

Specifications

| Reflow Soldering (with Formic Acid Option) | ||

|---|---|---|

| Substrate size | : | Fragments to 160 mm |

| Substrate Thickness | : | Up to 10 mm |

| Vacuum Range | : | Atmosphere to 10-3 hPa or mbar |

| Oven Temperature | : | Ambient to 350oC |

| Ramp Up Rate | : | Up to 120 K/min |

| Gas Flow Control | : | Nitrogen at max. 5 normal litre per min |

Nikon IC Inspection Microscope with Digital Camera

Hot Plates (PHT-HP1 to PHT-HP8)

Clean/Semi-clean/Non-Standard

Laurell PDMS Coater (PHT-SC6) (Microfluidic user only)

Non-Standard

Kurabo PDMS Mixer/Deaerator (PHT-MX1) (Microfluidic user only)

Non-Standard

_small.jpg)