Thermal Diffusion and Ion Implantation Module

CF-3000 Implanter (IMP-3000)

Clean/Semi-clean

centrotherm SiC Oxidator 150 (DIF-SIC)

Clean

LPCVD HTO (CVD-HTO)

Clean

LPCVD (CVD-A2 to CVD-A4, CVD-B1 to CVD-B4)

Clean, Semi-clean

Diff. Furnace (DIF-A1, DIF-C1 to DIF-C4, DIF-D1 to DIF-D3, DIF-F1)

Clean, Semi-clean, Non-Standard

STS PECVD (CVD-P2)

Non-Standard

Oxford PECVD (CVD-P3)

Semi-Clean

Oxford ALD (CVD-ALD)

Non-Standard

NFF ALD (CVD-ALD-2)

Semi-Clean

Fiji ALD (CVD-ALD-3)

Semi-Clean

CNT PECVD (CVD-CNT)

Non-Standard

RTP-600S (DIF-R1)

Clean

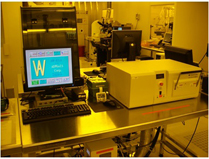

AG610 RTP (DIF-R2)

Semi-clean

AW610 RTP (DIF-R3)

Non-Standard

Specifications

| Wafer handling | : | Manual loading of wafer into the oven, single wafer processing |

|---|---|---|

| Wafer sizes | : | Small samples and 2", 4" and 6" wafers |

| Ramp up rate | : | Programmable, 10℃ to 80℃ per second |

| Ramp down rate | : | Programmable, 10℃ to 80℃ per second |

| Operating temperature in the range of 250℃ to 800℃ | ||

| Ion implantation annealing | ||

| Silicide formation, nitridation of thin gate, dielectrics & silicide, PSG/BPSG reflow | ||