Process Information

Standard Format

In order to save us time reading your process flows, you must put them in a standard format. It is not uncommon that the same process flows are rejected again and again due to the same kind of mistakes. So, you are advised to stick to the standard format (MS Word / Excel).

Heading

Each process flow must have a heading showing what you are going to fabricate. In the case that you don't use standard silicon wafers as substrates, you have to state clearly what substrates you are going to use. Supposing your substrates were 2-inch Ga-Nitride wafers. Then you must put the heading in this way:

"Process Flow of xxxxxx

Substrate: Ga Nitride Wafer, Dimensions: 2" in diameter x 525um thick"

8 Columns of Process Flows.

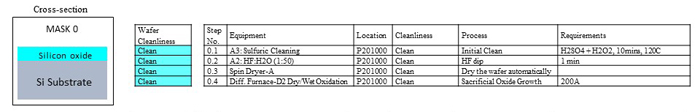

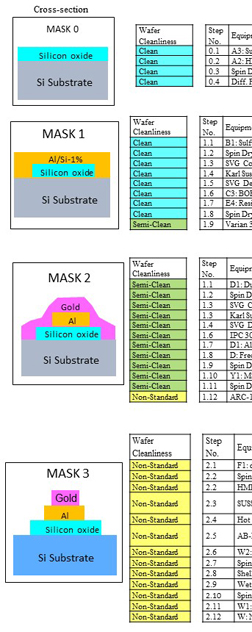

Each process flow is divided into 8 columns like this:

The functions and formats are listed as follows:

Cross-sections: Processes are grouped according to mask layers. Each picture is the cross-sectional  view of the sample after you have finished the processes shown on its right.

view of the sample after you have finished the processes shown on its right.

The processes under the heading of MASK 0 start from the initial treatment that you do on the substrate to the process immediately before the first photolithography. Similarly, MASK 1 includes the processes from the first photolithography to the one immediately before the second photolithography. Mask 2 and 3 are defined in the same way.

Wafer Cleanliness: Next to Cross-sections is Wafer Cleanliness, which is the cleanlinese level of your sample immediately after you have finished the process listed on that row. As to the way of evaluating the cleanlinese level, you can look at our Process Verification Scheme . Mind you, Wafer Cleanlinese must not cleaner than the Cleanliness of the equipment that you have used. Though it sounds simple, a great many of users are rejected for this reason.

Step No.: You can name your steps whatever you like. Nevertheless, you are strongly advised to use these reference numbers when you are booking equipment on the web.

Equipment, Location, Cleanliness: These three columns tell us the information of the equipment that you are planning to use. They are exactly the same as the data listed in the table of Cleanliness Levels of NFF (CWB) equipment . Since they are fixed and you have no room to play around, what you need to do is nothing more difficult than copying them direct from the table. Easy as it seems, there are a plethora of cases rejected due to users' failing to do so.

Processes: This column shows the short description of your process. Similar to Step No., the name of the process is advised to be used as references for equipment reservation.

Requirements:This column allows user to write down some additional information as to the thickness of the oxide to be grown, thickness of metal to be sputtered, and so forth. From this information we will know whether the process you are planning to do is viable. Otherwise, you will inadvertently push our equipment to the limit.